Performance Improvement Project - Cost Reduction & Value Chain Improvement

The company

Multi-Million USD Medical Technology Company UK performing electro-mechanical manufacturing, spares and services on site of 18,300 metre squared footprint, 150 employees and $50MM volume of production.

the challenge

Company focus for the site was cost and quality in an highly competitive environment.

It was necessary for the site to embrace Lean Production to become the highest quality and lowest cost manufacturer with particular focus on the next 3 years.

THE KALEIDOSCOPE APPROACH

Worked with the site management and teams to analysis and evaluate opportunities :

-To improve current quality levels in electronic box build without incremental inspection or rework costs

-For supplier qualification program that focuses on developing improved capability

-To establish an aggressive target around variation reduction

-To explore local assembly & distribution opportunities .Assess potential integration opportunities with other sites in the company’s network outside of the UK.

Implemented cost and profitability monitor for annual review

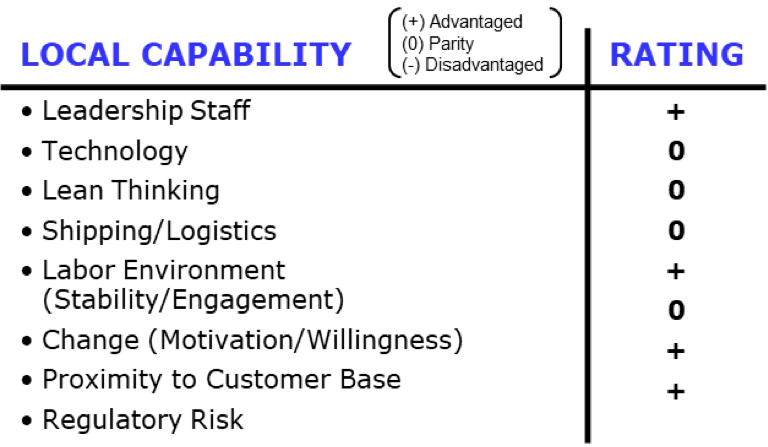

Performed on site / local team capability assessment

the results/benefits

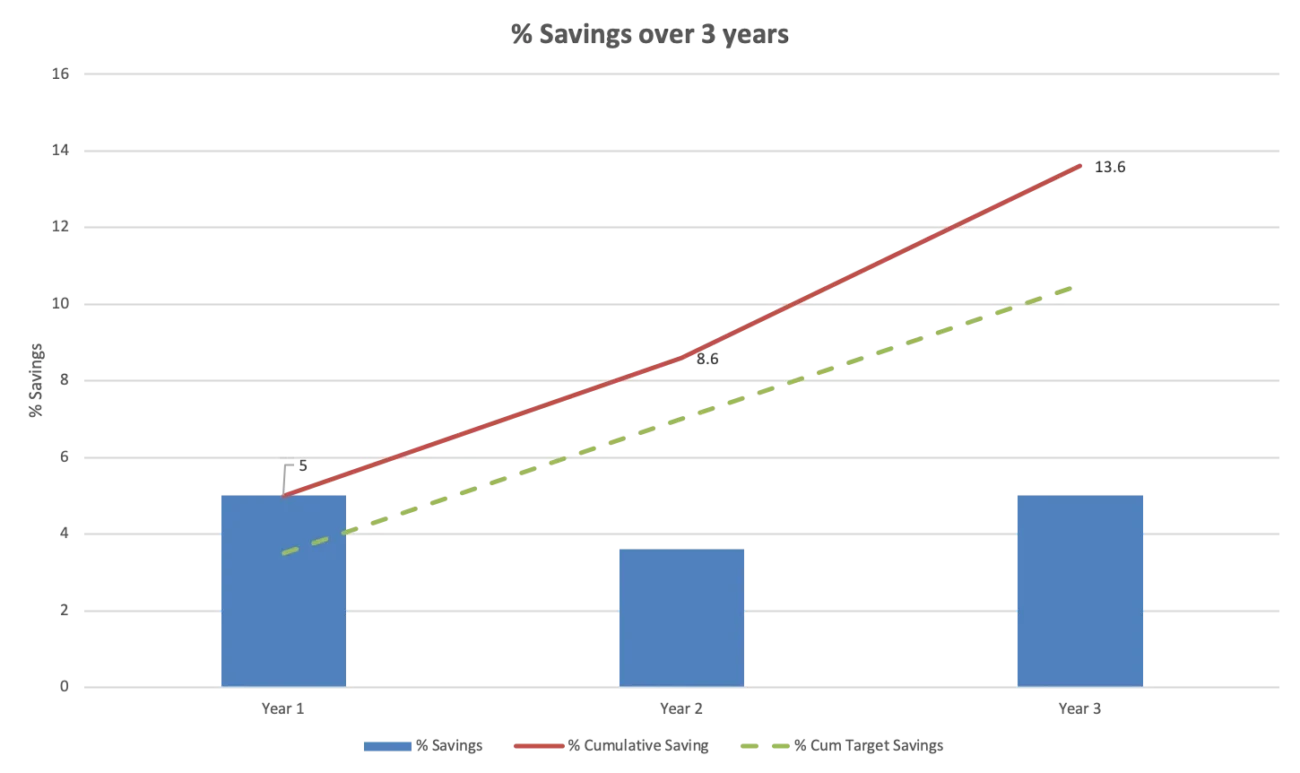

Over $7MM cost savings over 3 years, cumulative 13.6% savings over 3 years exceeding 10.5% target.

Quality, First Pass Yield 75% ( versus target 70%).