Strategic Project - Develop the Network Strategy for Supply Chain, Production & Sourcing

The company

Global multi-billion USD corporation that develops market-leading medical device across infusion, automated dispensing and patient identification systems,

The company was looking to significantly improve operating margin and operating cash flow, with payback required within 3 years on any cost investments made.

the challenge

Develop the manufacturing and distribution network strategy to deliver the most cost-effective locations for production, optimize manufacturing footprint and reduce production expenses.

Identify strategic sourcing and value engineering initiatives that could be undertaken.

Manage business continuity risks of concentration in fewer plants.

Ensure improvements to customer service and responsiveness.

THE KALEIDOSCOPE APPROACH

Kick off meetings with project sponsors and team and established business governance for this project.

Worked closely with business leadership to assess manufacturing and distribution current state. This included identifying the locations and performance of current facilities, evaluating their performances, capacity utilization, lead-times and customer service levels. Provided tools to easily allow the gathering of data on transportation, inventory and warehousing.

Defined clear business objectives and manufacturing network priorities, to both make visible and ensure alignment. We categorized these into 4 areas which were constantly revisited – Reduction of total operational costs; Improvement of Inventory efficiency; Lean and agile supply chains (distribution network) ; Other implications such as Merger and Acquisitions, Tax efficiency.

Analysed market and customer needs. This included factors such as demand patterns, geographic distributions, order sizes,, lead time expectations and service level requirements.

Evaluated supplier and partner relationships. In particular, we sought opportunities for collaboration, consolidation or integration within the network.

Based on the analysis and modelling, we were able to propose optimal locations within the network. Created an implementation plan that outlined the actions to transition.

the results/benefits

Delivered a 3 year strategic cost change per unit saving including purchased materials of 17.2% (versus best in class benchmark of 15.9%); Circa $130 Million savings over 3 years.

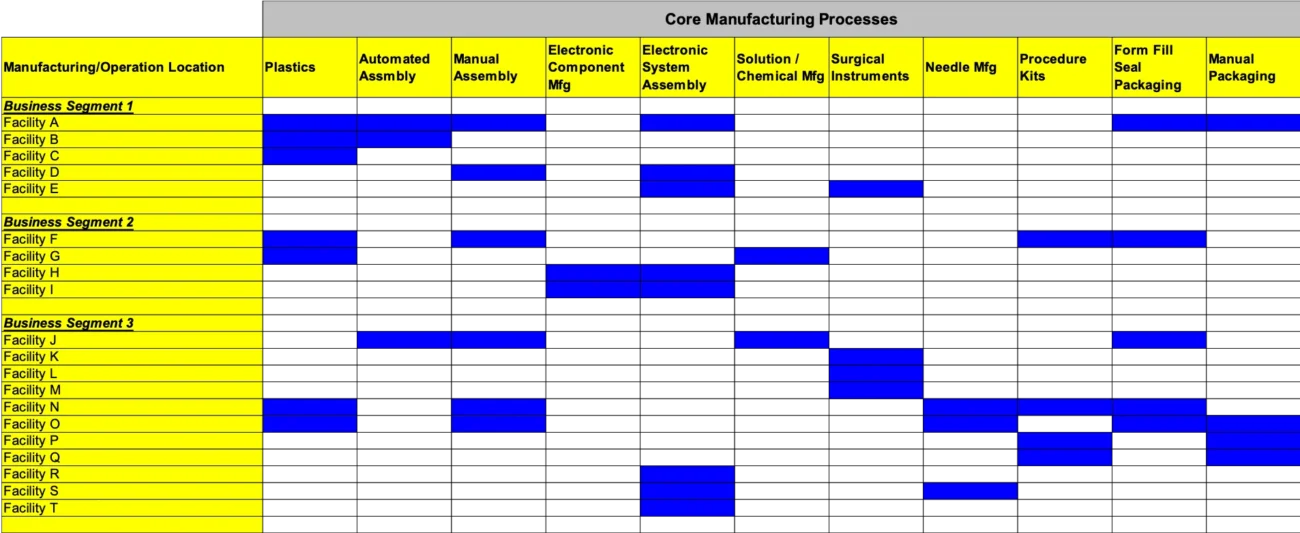

Recommendation for a network of manufacturing core processes to drive business completeness – service, quality and basis for future innovation.